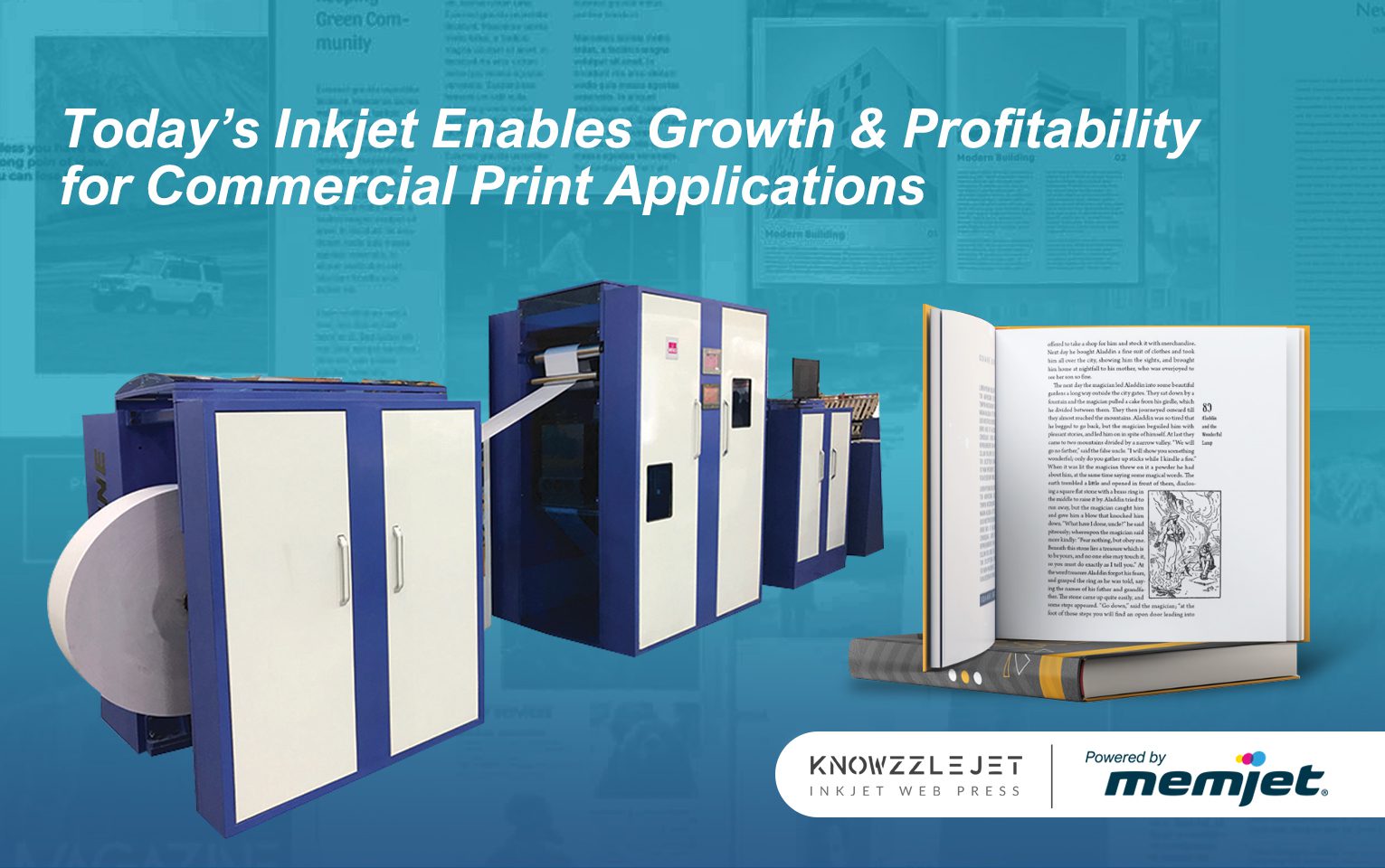

Think about it – commercial printers can now produce their own packaging. A flexo label provider can start offering digital labels. The print industry is quickly evolving.

This evolution can be seen in the growth of the print industry over the past three years. SGIA reports the industry has not grown because printers are producing more of the same types of jobs; the growth is coming from printers who are combining ingenuity with new printing technology to expand into new markets and offer products they have not previously been able to.

And Memjet OEM partners are keeping pace with this trend, creating solutions that provide the flexibility, affordability, and quality needed to capture opportunity in this new business environment.

But what enables printers and OEMs to keep pace in this fast-moving market?

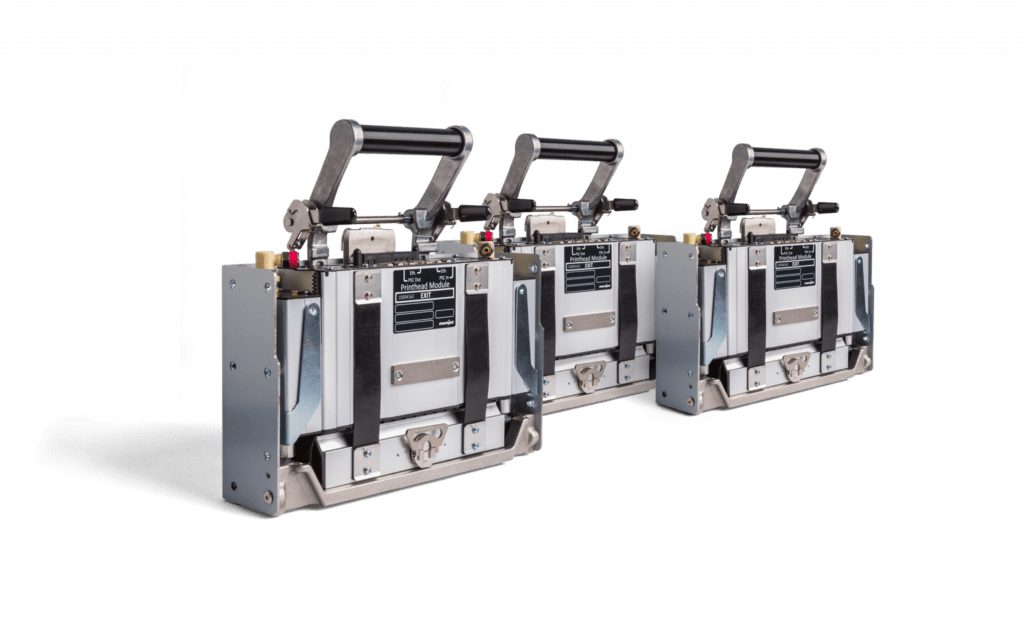

Modularity.

Most printhead manufacturers provide the printhead and leave sub-system development to the OEM partner. Memjet’s DuraLink technology is different. Our technology is delivered in modules to give OEM partners the building blocks they need to quickly and easily develop the printing systems for their target markets and end users.

In today’s fast-moving print market, OEM partners need resources that can speed up product development and bring products to market faster and more efficiently.

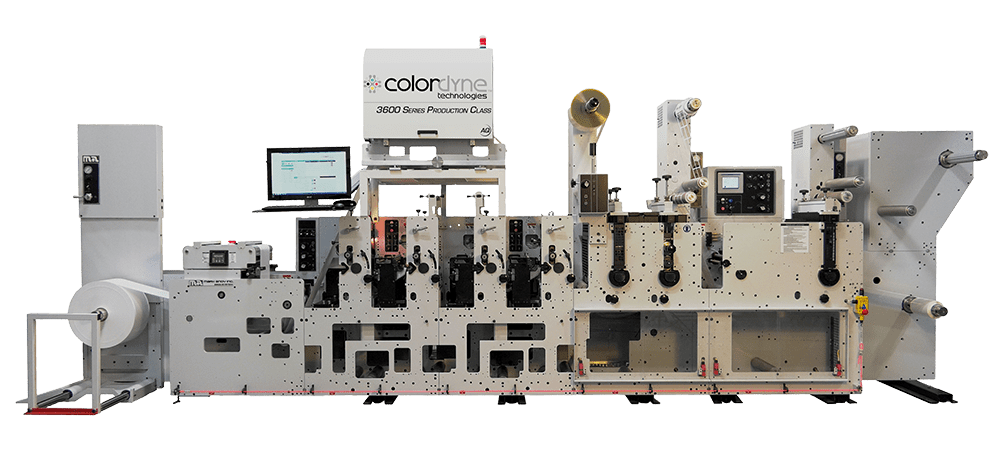

Last fall, Colordyne became the first OEM partner to announce the development of a new print engine, powered by DuraLink, for commercial, packaging, labeling and industrial markets.

This engine, Colordyne’s second-generation 3600 Series water-based technology, uses aqueous pigment inkjet to deliver flexibility and scalability at an affordable price point.

Combining the precision and quality of water-based inkjet with printhead life that is ten times longer than other aqueous printheads means higher image quality, enhanced durability, and the capabilities needed to capture new opportunities.

Colordyne is an excellent example of what can be accomplished using Memjet’s modular technology. The 3600 Series water-based pigment technology will enable Colordyne and their sub-OEM integration partners to successfully deliver on their business plans and stay ahead of the competition.

See It All In Action

Later this month, Colordyne will host an open house that brings together sub OEM integration partners, suppliers, and customers for a series of presentations. At the event, I will discuss the impact modules make on the development of printing solutions. Attendees will also get to see Colordyne’s new pigment ink technology and product demonstrations from Colordyne’s full suite of solutions.

This event will be held on March 27. People interested in attending can visit the Colordyne website and complete an interest form.