The opportunities in cannabis packaging have been getting a lot of buzz right now – and for a good reason.

Changes in laws and the development of new products have led to an increased demand for cannabis-based products.

But this opportunity is not without its challenges. In this post, we look at the trends and regulations driving the cannabis market of today and provide insight into how to produce labels to meet that changing demand.

Today’s Cannabis Market

Opportunities in the cannabis market center around two main types of cannabis: (CBD) and Cannabidiol Tetrahydrocannabinol (THC). THC is the psychoactive cannabinoid that is responsible for the “high” from cannabis use. CBD is a non-psychoactive cannabinoid used in a variety of products.

Over the past five years, sales of types of cannabis products have increased dramatically.

Canada and 11 states in the US have approved full cannabis legalization that enables recreational sales at licensed dispensaries. More states have legalized cannabis for medical purposes, and 15 states have decriminalized the use of cannabis.

Experts predict that federal legalization of recreational cannabis will become a reality within the next ten years, opening up even more market potential.

The market for CBD products is also growing, as manufacturers produce more CBD infused salves, creams, and balms for sale in retail stores.

In 2018, the entire cannabis industry – including recreational sales, medical sales, prescription drug sales, and retail CBD sales – generated about $10 billion in revenue. By 2024, this number is expected to surge to about $30 billion in revenue, representing a CAGR of around 20 percent.

Meeting the Need for Cannabis Packaging

To effectively produce labels and packaging for cannabis, you first need to understand its unique set of demands.

To start, marketing opportunities for cannabis is limited – there’s no print ads or online advertisement allowed. This lack of traditional marketing means that the label must create a connection with the consumer with colorful messages and images.

Cannabis products also have strict labeling requirements. Each label must include critical information like dosage, ingredients, warning statements, and intended use. These regulations not only vary by state, but they are also subject to change regularly.

Finally, cannabis customers want the same clean packaging they demand from other consumer packaged goods. Labels and packaging must be produced in a sustainable, environmentally sensitive way.

Inkjet Meets Cannabis

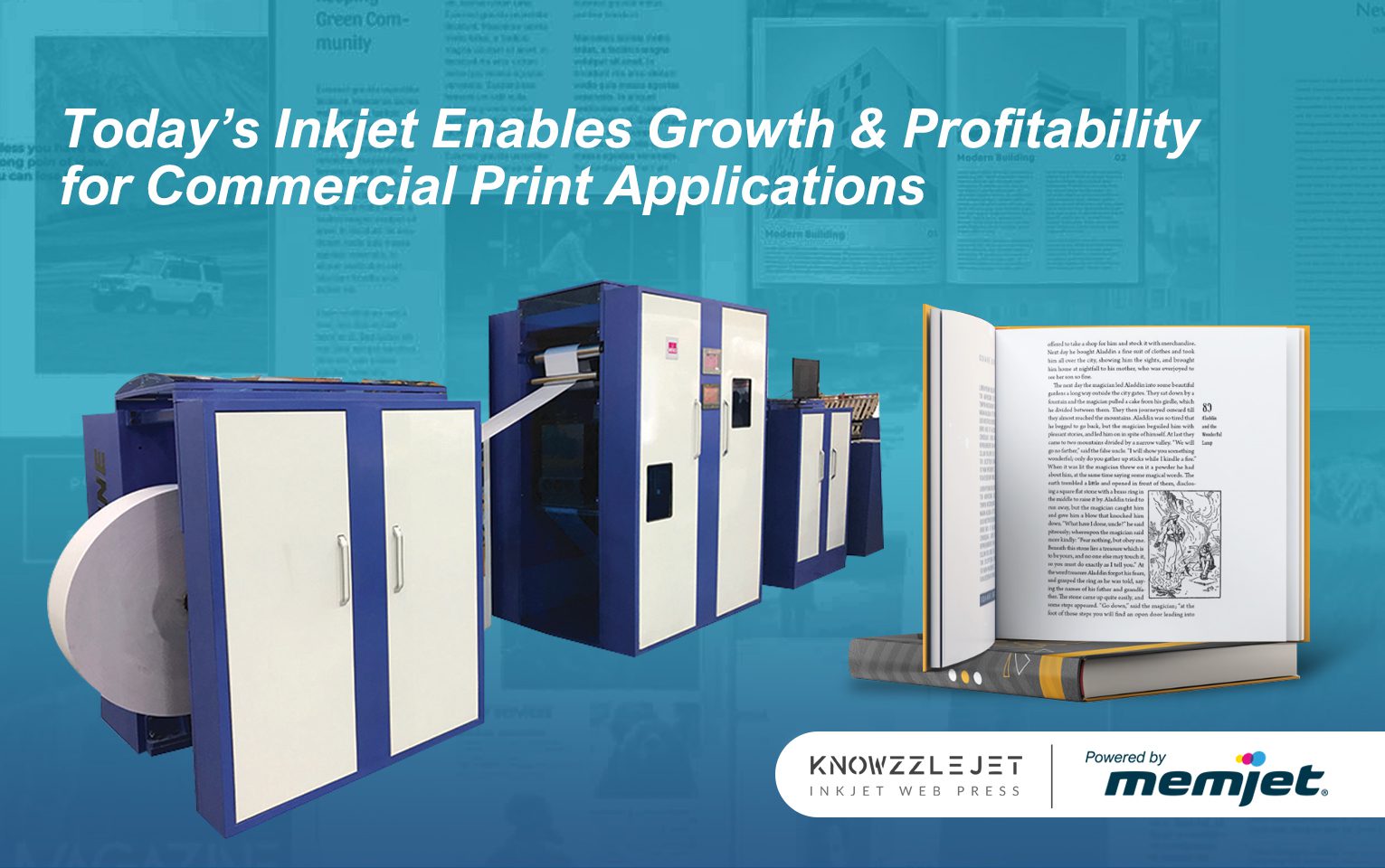

Inkjet printing is uniquely positioned to meet the demands inherent in cannabis packaging and labeling.

The variable data printing capabilities of inkjet solutions ensure that printers can comfortably accommodate the changing regulations – while still gaining efficiencies in their operations.

Inkjet’s high resolution and stunning print quality ensure that the labels have the beautiful precision they need to impact and engage the consumer. Memjet’s water-based inks ensure the label is less harmful to the earth and people than other ink alternatives.

Printing systems Powered by Memjet’s single-pass print technology enables blazing fast print speeds from entry-level print solutions up to high-volume presses, an important consideration for the growth rate expected in this market.

With so many advantages, it’s easy to see why cannabis manufacturers are turning to inkjet. Research done by PMMI reports that when cannabis manufacturers begin to print their packaging, even manufacturers with no print experience start with digital label production.

Create Your Opportunity

These are early days for the cannabis industry, but opportunities are taking shape.

New research from Smithers called The Future of Cannabis Packaging to 2024 forecasts that as the cannabis market evolves, the value of packaging for legal cannabis products will experience a year on year growth rate of 24 percent – exceeding $1.63 billion by 2024.

That means the time is now for equipment manufacturers to address this market. Start by gaining insight and understanding on the unique demands of this market. Then, offer recommendations on what procedures – like label and package production – can be automated and/or transitioned to in-house production.

In following this advice, you can become a true partner, and ensure the success of both your organizations.

Connect with us on LinkedIn.