In an industry that’s slow to change, change is what it’s going to take to survive.

It’s getting personal

Or maybe I should say, “personalized.” With the market for personalized print showing no signs of slowing, the customization craze isn’t a craze at all, but rather an indication that people will continue to want their print, their way. As the shift to meet increasing demands for personalization persists within the market, manufacturers and printers of all types will need to create and provide the solutions that make this growing market possible—namely faster, higher quality, more affordable digital printing technology.

One example of the rising demand for personalization is the continued success of online photo-printing service Shutterfly. With 16 billion pictures on their servers destined to adorn everything from photobooks to greeting cards, calendars and even custom ceramic mugs, the company prints memories by the millions.

One example of the rising demand for personalization is the continued success of online photo-printing service Shutterfly. With 16 billion pictures on their servers destined to adorn everything from photobooks to greeting cards, calendars and even custom ceramic mugs, the company prints memories by the millions.

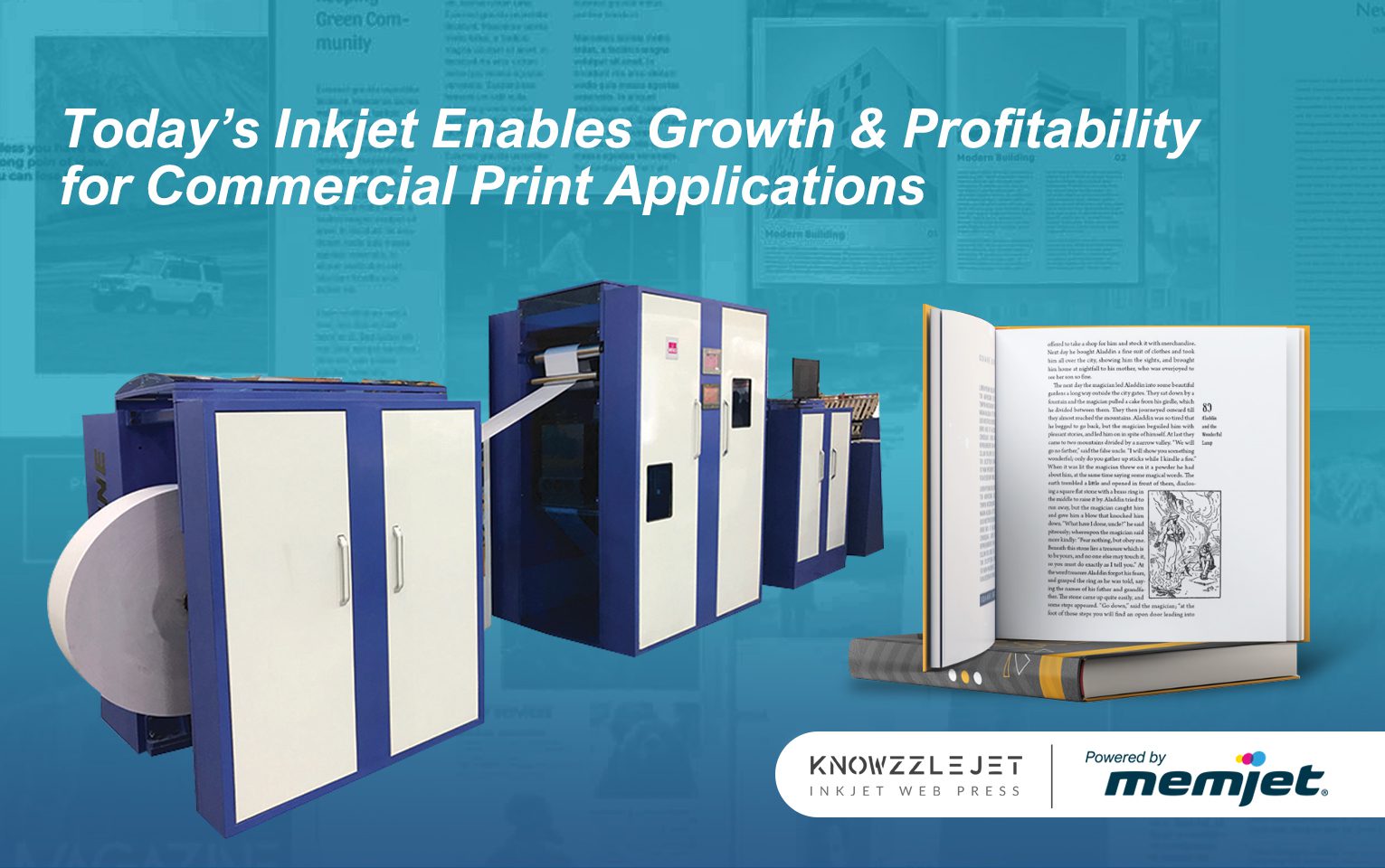

At the crux of the customization uprising is technology that is fast, flexible, and affordable. I’m talking digital inkjet technology—and the higher quality and faster turnaround times that come with it. According to the 2017 Drupa Global Print Report, the growth of digitally printed packaging is on the rise, with 34% of packaging printers offering digital inkjet print—up from 24% in 2014. The report shows inkjet is now the dominant technology for most applications with a 74% share of the digital print market in 2016. Digital printing will also continue to grow rapidly in commercial and wide format applications.

A time to adapt

Digital print market to reach $187.7 billion by 2018

The projections are clear: In 2018, digital printing will play a vital role in supporting a printer’s growth. And as improvements in productivity and reliability make digital printing more cost-effective over higher runs, it stands to gain even more market value while offset processes continue to see a decline in market share. In an industry that’s resistant to change, the rise of digital isn’t something printers can afford to ignore any longer.

So why are some printers still reticent? Reasons for dodging digital range from nervousness about adopting change, to questions about capabilities and even concern about changing a traditional sales approach. But if there’s ever been a time to adapt in order to meet changing market demands while also improving efficiency and automation, learning new skills and adding valuable new services, it’s now.

Analog just doesn’t support the variable personalization and customization, versioned prints, and fast turnaround times the market demands. Moreover, a new study from Smithers Pira shows offset shares falling while the digital printing market grows from $131.5 billion in 2013 to $187.7 billion in 2018. These forecasts are hard to ignore.

Three keys to success: Speed, quality & vibrancy

As the market for variable printed products grows, print speeds will have to get faster to keep up. We’re seeing an increase in package printing, including food and beverage and corrugated boxes, as well as labeling and specialty products like ceramics and tiles. These jobs require faster turnaround times and shorter runs. But printers and manufacturers can’t hang their hats on speed alone. Staying competitive in 2018 will require a dynamic combination of speed, quality, and vibrancy. Customers are looking for digital platforms with near-offset quality and vibrant ink solutions at groundbreaking speeds.

How printers & manufacturers can thrive in 2018

As printers look to add digital solutions in order to open up to new markets, they need to do their homework. Using the aforementioned speed, quality and vibrancy as a guide, printers should seek rapid presses that offer quick turns, print quality of 1200dpi or higher, and excellent ink formulas that meet the needs of their specific market.

As printers look to add digital solutions in order to open up to new markets, they need to do their homework. Using the aforementioned speed, quality and vibrancy as a guide, printers should seek rapid presses that offer quick turns, print quality of 1200dpi or higher, and excellent ink formulas that meet the needs of their specific market.

With more and more printers creating hybrid press solutions, printers may also consider retrofitting existing flexo presses with digital capabilities. These hybrid presses bring new life to existing equipment and enable the printer to more easily make the transition to digital printing.

Lastly, printers should seek digital press solutions that offer the best output at a low total cost of ownership that will enable not only rapid printing but also a rapid return on investment.

Just as printers need to adapt to market changes, OEMs will need to build better, faster, more affordable solutions in the digital space. This is the time for OEMs to fill the advisor role, consulting with end users and showing the strengths of their solutions.

Finally, printing is no longer just happening at the print service provider. The affordability and flexibility of digital printing has consumer brands, manufacturers and small retailers bringing their printing in-house. OEMs need to be mindful of the demands of this new market segment.

Want to stay out in front? Embrace change

Change happens slowly in this industry, but it does happen—and it’s happening now. Regardless of the markets you serve or the regions you work in, if you want to succeed in the long term in the print industry—or any industry—you must adapt to changing market and economic conditions. Now is the time for printers and OEMs to work collaboratively in order to stay out in front and build the future of print together.

For a closer look at companies already embracing these changes, watch these packaging companies and their solutions in action! Or if you have questions about any of our packaging solutions, please email Alicia at alicia.chavez@memjet.com. We’re here to help guide you to the best solution.