Creativity is a tricky thing. It can be elusive and difficult to quantify, much less define by R&D standards.

It’s rooted in trust and openness. The key is to give people the freedom and space to solve problems in the right way. Sometimes that means making mistakes, but mistakes can lead to innovation and elegant solutions. That’s the thing about R&D.

The path to developing a successful new modular platform at Memjet was not a straight one. It was the result of listening to our OEM partners, exploring what we could do with advanced technology, and trying things out before converging upon a clean, elegant solution.

The power of Memjet’s chips

In 2004, I was working as an electronic engineering project manager when a friend told me about work he was doing with a company called Memjet. It sounded intriguing.

I was an experienced chip designer, but the Memjet printhead chip was unlike any I had worked on before. Not alone do you have all the usual electronic problems of power and heat, but the printhead chip itself has channels and holes running through it for ink flow. The chip was a really unusual piece of silicon and a fascinating design, and it sounded like something that would be extremely interesting to work on.

When you have a fast, page-wide printhead chip integrated into an A4 printhead, the next challenge is to get enough correctly formatted data into it at high speeds so the dots end up on the page at the right time. For that, we designed a print engine controller with a high-speed data path since there was nothing on the market that even came close to the performance we needed.

The path to modularity

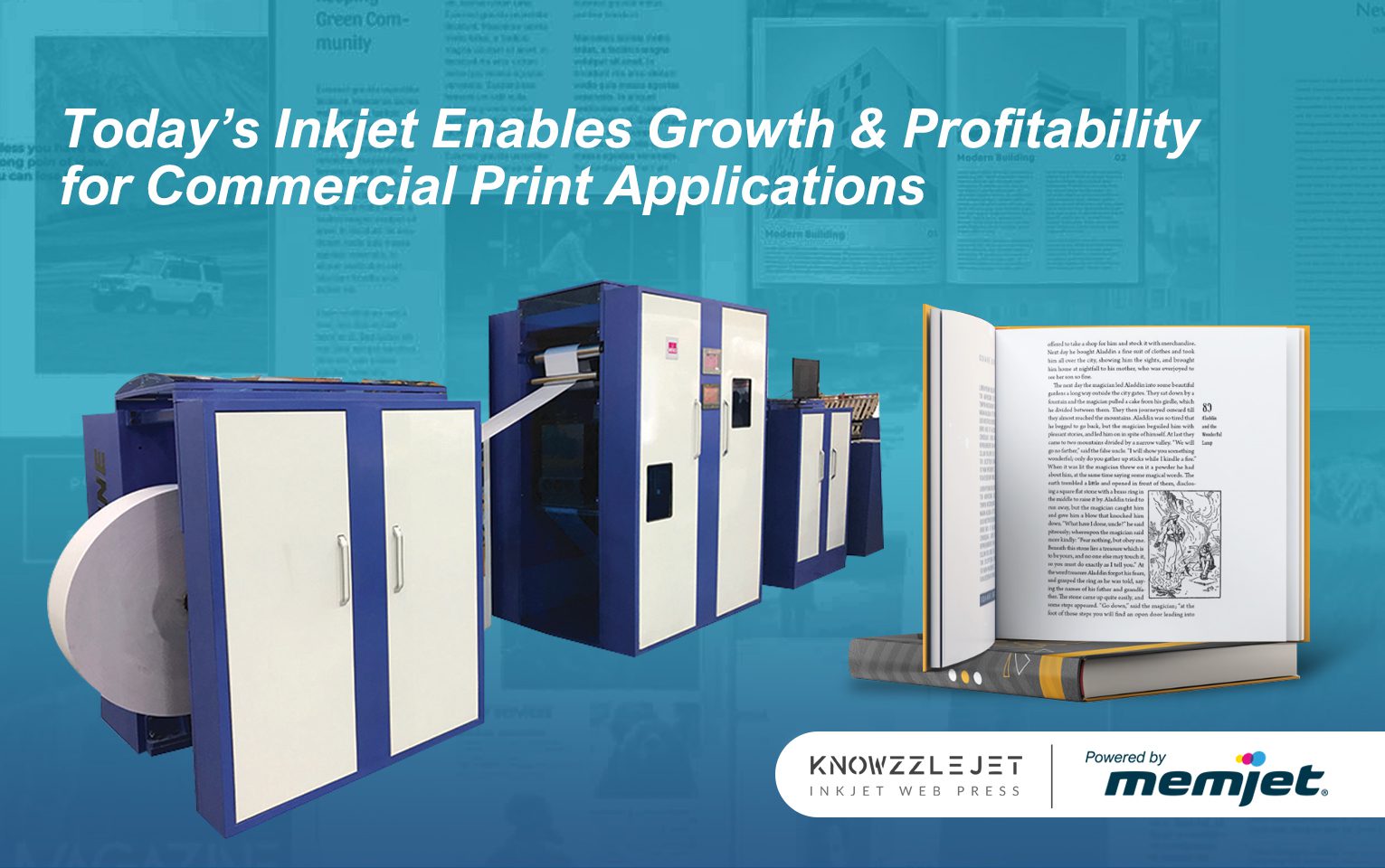

Working with printheads is not an intuitive process. So rather than leave our OEMs to struggle with fitting together different parts from various suppliers and hoping to create a working printer,

Memjet wanted to make it as easy as possible. We asked OEMs what they and their customers really wanted, and put our minds to developing a streamlined process that would enable our OEMs to go to market faster.

We came up with a solution that would supply the printheads and the data path as one complete module that could be stacked up to add width or colors as needed.

This modular, Lego-like approach allows our OEMs to design and build custom printers people want to buy and can afford. It abstracts away all the Memjet-specific formatting and protocols so that OEMs can focus on what they do best. OEMs can take components off the shelf, stick them together and away they go. They’re printing.

The Secret to R&D: Trust more and listen harder

What I love about Memjet’s culture is the freedom you have to explore. Every voice and idea is heard. Your idea might sound crazy or unorthodox, but either way, colleagues and executive management will listen to you and offer feedback that helps improve on the original idea.

At the same time, we listen carefully to what our partners want. There’s no point in designing products that aren’t what people want, so we really want to hear what they’re saying.

Our ability to listen plays a considerable role in our success—it informs and inspires our research. And you can’t land on a new development without putting in the research. There’s a reason it’s called R&D. The most significant inventions in history didn’t happen on the first try. Success happens when we learn to accept trial and error as part of the process, and then do it again and again until we’ve really got something.

Learn more about Memjet’s R&D culture and watch a video at www.memjet.com/about/our-services