The world of print is experiencing a shifting paradigm. Gone are the days of big orders and large print volumes. Today, shorter print runs, increased customer demands, and fast turnaround are the driving factors in print.

To succeed in this new environment, printers need to think differently. They need solutions that can support them as they make the shift in their business models. In this post, we’ll take a look at a printer who used a new way of thinking and the right solutions to move in a new direction – twice.

From Toner to Inkjet

Based in Birmingham, Alabama and Dallas, Texas, High Cotton is a printer that was facing the challenges many printers experience. Their current toner-based legacy equipment was showing its age, and to remain competitive, the company wanted to transition to being a “white paper” shop that could offer value added services like color and variable data.

But High Cotton had an additional challenge: Their business was split geographically into two facilities that were run independently. Monthly print volumes were split across both locations. As the company looked to expand, they also needed to decide where and how that expansion would happen.

Two for the Price of One

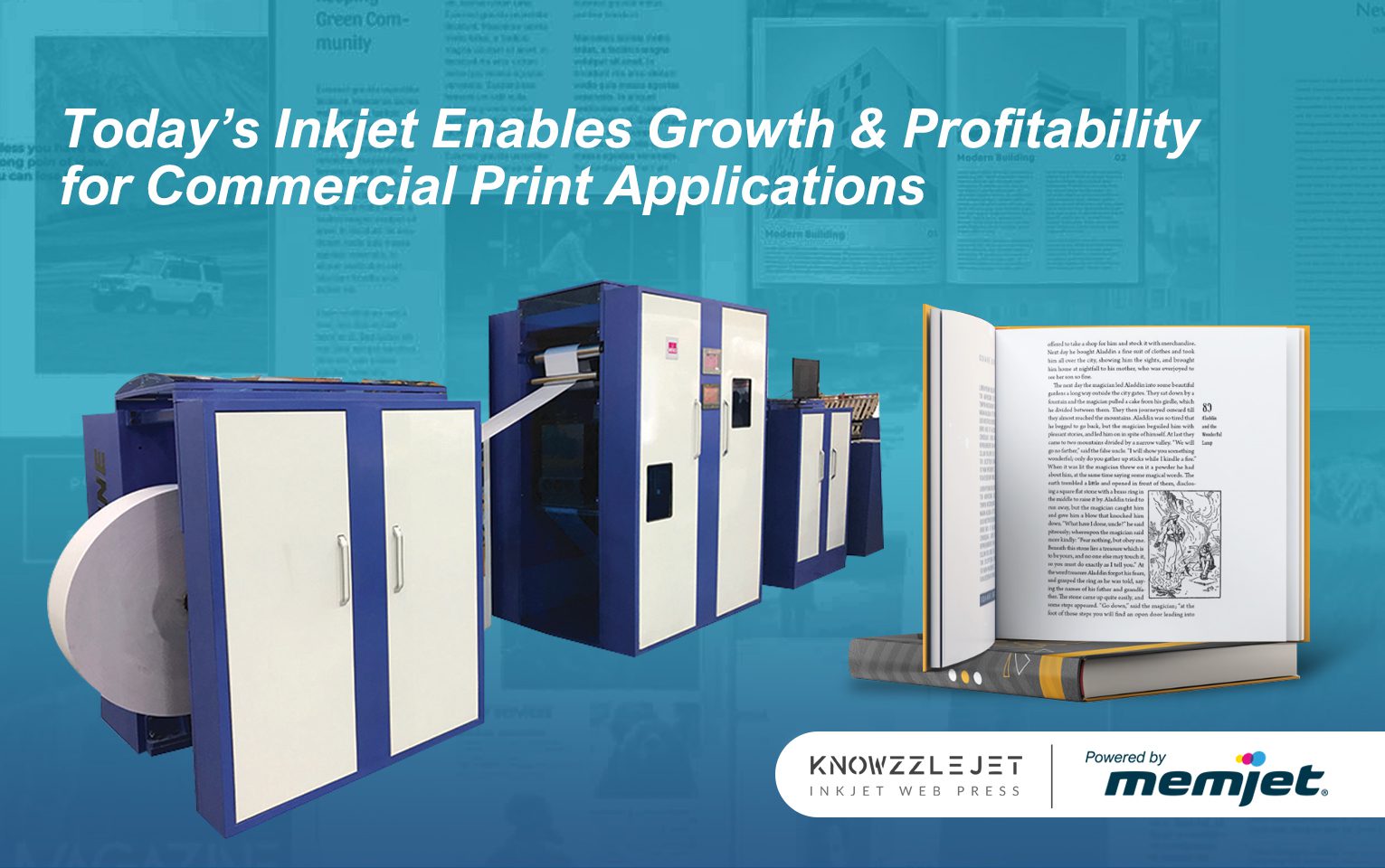

After researching their options, High Cotton learned they could afford to install two Super Web Digital WEBJet 200D commercial presses, one for each location, for the price of one competing press.

The 200D not only met their productivity and cost requirements, it also enabled High Cotton to affordably integrate the finishing requirements they needed to support their expanded business offerings.

As Tommy McGahey,CEO of High Cotton USA notes, “We looked at all the competing inkjet technology, and the price point of the Super Web hit just the right spot for a company our size.”

A New Way of Doing Business

After installing the SuperWeb, High Cotton was immediately able to realize the benefits of the solutions and shift their business models in both locations.

High Cotton is now a “white paper” shop, offering a range of solutions to meet their client’s needs and grow their business.

For example, most of the company’s previous work was monochrome, using toner based equipment on preprinted shells. Today, High Cotton provides customized statements with targeted, full color inserts that give their clients a way to add promotional messages to their communications.

These full-color, variable data capabilities have enabled High Cotton to expand into markets they had not been able to service before.

Most importantly, the WEBJet 200D has increased the productivity of both shops, allowing them to better service their clients and support their expanded business.

So with a new way of thinking, and the right press, High Cotton has been able to provide new services, open up new business opportunities, and increase productivity.

That’s rocking.

To read the full case study, click here.

Learn more at drupa 2016

Memjet will be showcasing their solutions at drupa 2016, which will take place from May 31 to June 10, 2016, in Düsseldorf, Germany.

drupa attendees can see innovative printing technology at the Memjet stand (C24) in Hall 5. Visit rockyourprint.com to learn more about Memjet at drupa.