By Kim Beswick, General Manager-Benchtop & Minipress, Memjet

The number of manufacturers who have adopted inkjet-powered labeling solutions has climbed steadily over the past few years. This year, we saw a new trend emerge: after achieving success with labels, many manufacturers are also adding next-generation inkjet packaging solutions to their operations.

Are you thinking of making the same move? This post proves why in-house label printing has been successful for manufacturers, and why adding packaging to your operation promises similar positive outcomes.

LABELS AT THE FOREFRONT OF THE CUSTOMER CONNECTION

Research by Responsys states that sixty-one percent of U.S. consumers feel more positive about a brand when the marketing messages are personalized. More than half – 53 percent – are more likely to purchase a product when a brand personalizes communications.

The importance of this connection is especially clear when it comes to labels and packaging. The label and package are the metaphorical face of the product, whether it is used on the product or on the exterior shipping package.

Creating that level of emotional connection with consumers is one of the main reasons that many manufacturers now produce their own labels. Making label production part of their operation not only gives these manufacturers control of the message and product information, it does so at an affordable cost.

EXPANDING THE DIGITAL OPPORTUNITY TO INCLUDE PACKAGING

This success has resulted in an increased adoption of digital label printing solutions and is opening up the potential for growth in digital package printing solutions.

According to research firm Smithers Pira, analog packaging is growing by approximately 28 percent per year, which is expected to continue through 2018. But digitally produced packaging is expected to increase by 375 percent by the end of next year.

This research confirms what manufacturers are starting to learn: the value of inkjet printing is not limited to labels. Using inkjet solutions for package production can be an ideal progression for manufacturers who are looking to boost their efficiency, productivity, and brand awareness.

LABELS AND PACKAGING: THE POWER OF CHOICE

Having both inkjet-powered label and packaging printing solutions means manufacturers always have the right solution for creating colorful branded packaging. They can either produce labels to go on their packages or print directly on the packaging itself.

Let’s take a closer look at the benefits of each of these options.

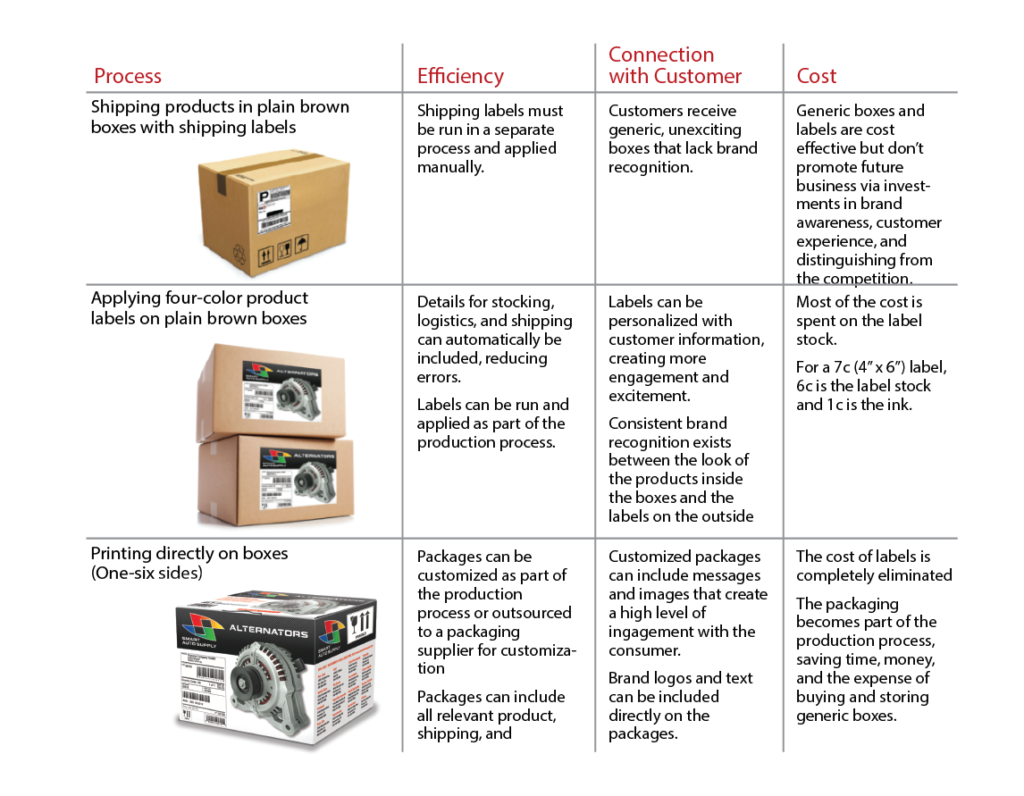

For many manufacturers, printing labels gives them the look they need to customize both the products and the package that ships the products. These manufacturers simply print a label for the product and then print a similar label for the shipping box. In doing so, they can leverage the same print solution and create the same look and feel between the product label and the package label. This is an easy, consistent way to leverage the look of the brand.

The downside of this approach, however, is cost. On a printed label, the label stock itself makes up 80 percent of the cost. This means that producing enough labels to cover an entire box can be expensive and may still leave a lot of blank, unbranded space on the package.

In addition to expense, printing and applying labels is a two-step manual process that is prone to errors.So, for some manufacturers, it makes sense to print directly onto the package. Starting with a plain box, manufacturers can easily print larger images on all sides in a single-step process. The output is more visually appealing, more impactful, and less expensive than covering the entire box with labels.

THE PACKAGING CONTINUUM

This chart compares the different package printing processes to help you understand when it makes sense to print a label and when printing directly on the package is the right option for you.

THE POWER OF INKJET FOR LABELING AND PACKAGING

Inkjet technology powers a wide range of affordable solutions that make high-quality color package production a reality and enable manufacturers to better balance the demands of their growing businesses.

Like the inkjet-powered labeling solutions, these package-printing solutions are available at a low cost of ownership. The small footprint and ease of use of these solutions mean that they can be easily incorporated into the manufacturers’ operations.

Once installed, this technology allows manufacturers to produce the type of packaging that advances their business goals.

Manufacturers can easily produce short runs of customized packaging in high-quality color. Each package that gets printed—no matter what the quantity—promotes a consistent, enhanced look for the brand’s image. Furthermore, this type of colorful, customized packaging creates a connection with the consumer that plain, unbranded, or minimally branded packaging can never achieve.

Inkjet package printing also makes financial sense for the manufacturer. Using inkjet to print packaging on demand means manufacturers can do away with costly, high-volume pre-printed packaging. This not only saves money, it also reduces waste and gives manufacturers better control of their inventory.

LEARN MORE

Earlier this year, Memjet published a white paper on the topic of the evolution from labels to packaging. Follow this link to download your copy.