By Marc Johnson, Director Global Product Management at Memjet

Printing on corrugated – boxes for shipping and retail display – is undergoing a dramatic shift. Before COVID-19, Smithers market studies showed this $130 billion market growing at a healthy CAGR of over 13%. Recently released data, now well into the COVID-19 crisis, shows that corrugated print produced using inkjet technologies will grow at a CAGR of nearly 20% through 2025.

What’s driving that growth? In addition to the overall trend of consumers buying more products online, three trends are changing the very nature of corrugated boxes.n

Functionality

First, what used to be a utilitarian “brown box” solution has now become more tightly integrated into the consumer’s overall experience. Brands are rethinking the function of what a box does – it no longer is just a protective package for the valuable contents inside, the box itself is now viewed as an integrated part of the buyer’s experience. Whether right-sizing the box to reduce the amount of packaging materials, using the box itself (inside and out) to advertise the brand or retailer, or even customizing the box with personalized messaging, the ability for the box itself to do more is now a reality.

On-demand

The second thing changing is how the corrugated box is made. Companies are revolutionizing box-making with “on-demand” right-sizing solutions that create custom-size boxes to eliminate inventorying multiple sizes, reduce voids/wasted space inside the box, better protect contents, increase sustainability, and reduce shipping costs.

Inkjet Technology

Third, inkjet printing technology can now meet the quality and production speed requirements for the entire box – not just marking and coding. Inkjet technology, like Memjet’s DuraLink platform, can print at speeds that can keep up with the production line (around 15 boxes per minute) with high-resolution full color. More importantly, every box can be different, eliminating the need to warehouse pre-printed boxes, and the time and labor of positioning and selecting from multiple sizes.

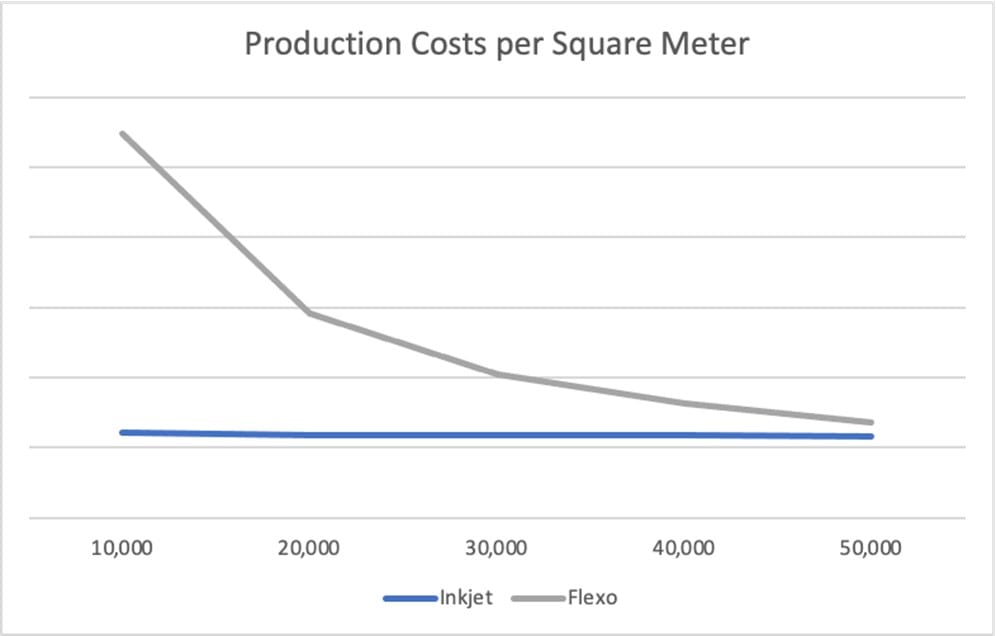

When evaluating the printing costs of inkjet compared to conventional flexo printing, many companies are surprised to find that inkjet is competitive beyond short-run or prototyping. In one recent TCO analysis, a corrugated box printer was able to show that inkjet was competitive at production-scale, in the tens of thousands of boxes per month, by eliminating expensive plate making, multiple steps of labor-intensive prep, handoffs, inventory, and waste/spoilage.

# Stay tuned for more on how Memjet is helping to power this radical – and exciting – change in corrugated!

Explore Powered by Memjet print solutions for packaging.

Connect with us on LinkedIn.