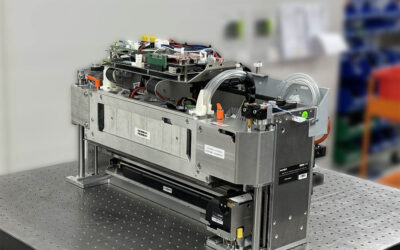

SAN DIEGO — April 19, 2023 — Memjet has today announced the launch of a turnkey printing solution, the DuraBolt 325C PrintEngine. This high-volume, integrated print engine is augmented by a sophisticated Digital Front End (DFE) that streamlines interaction between the print engine and all aspects of the printing process. DuraBolt is easy to integrate and operate and delivers high speeds, precision print quality, and broad functionality.

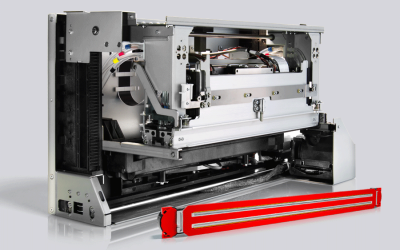

The DuraBolt 325C PrintEngine was purpose-built for high-volume print runs to deliver CMYK color for sheet-fed, web-fed, simplex, and duplex printing. Leveraging Memjet’s proprietary printhead technology, DuraBolt provides precision color distribution at print speeds of up to 450 feet per minute (135 meters per minute). The DuraBolt 325C PrintEngine prints images up to 12.77 inches wide, using a tandem head design including two print heads. Each printhead can jet up to 240 liters of ink and deliver four times nozzle redundancy for every color. It can achieve print resolutions of up to 1600 x 1280 DPI, and can be used for extended production print runs with low maintenance requirements.

The DuraBolt PrintEngine’s digital front end (DFE) is built to support DuraBolt’s flexible solution architecture. This delivers powerful process control and system automation, and streamlines the interaction between the print engine and all aspects of the printing process. The Human Machine Interface (HMI) gives operators an intuitive and interactive dashboard as well as real-time status of consumable levels, press components, and environmental conditions.

The combination of such a robust printing engine and powerful control architecture delivers a solution that provides rapid integration cycles and time-to-market for OEMs, and straightforward user operation and productivity for their customers. DuraBolt answers industry calls for technology that is easily operated by cost-effective, non-expert print operators.

Using Memjet’s durable pigment, fast-drying aqueous ink, the DuraBolt 325C PrintEngine delivers high image quality across a wide range of commercial printing, industrial and packaging applications. Memjet ink is an environmentally friendly ink that has been developed for use on food packaging and indirect food contact applications.

Memjet’s Chief Technology Officer, Jason Thelander, explained that DuraBolt’s advanced printing profile, ready-to-deploy build and ability to integrate with third-party technologies create a unique value proposition.

‘DuraBolt helps our partners capture significant efficiency gains. You have reduced upfront development costs plus shorter maintenance cycles. Think rapid engine start-up, exceptional print speeds, extra-long print runs, automatic calibration, and reduced maintenance and you have a print solution that can deliver genuine competitive advantage,’ said Mr. Thelander. ‘It’s a turnkey solution designed to mesh with existing infrastructure and fast-track commercialization.’

The new DuraBolt solution line from Memjet will extend and complement Memjet’s existing printing system lines which include VersaPass, DuraFlex, and DuraLink.

About Memjet

Memjet is the global leader in digital inkjet technology. With a focus on precision, simplicity, and affordability, Memjet approaches the world of print from its partners’ perspectives, understanding the challenges they face, the barriers they must overcome, and the contributions they make. Thoughtfully combining innovation and imagination, Memjet produces exceptional printing technologies that enable OEMs to explore new opportunities, grow their businesses, and generate ROI.

Memjet has offices in San Diego, Dublin, Sydney, Taipei, Singapore and Boise, Idaho. The company is privately owned. Follow Memjet on LinkedIn and Twitter @memjet.

Media contact:

John DiVincenzo

Director – Product Management

Memjet

Ph: +1 585 820 4341

E: john.divincenzo@memjet.com