San Diego — Memjet (www.memjet.com) transformed the printing industry when it released its first inkjet technology 10 years ago. Today, Memjet announces the release of an additional inkjet technology platform called DuraLink. This groundbreaking digital printing platform combines long-life printheads, pigment ink and flexible modules to give OEM partners a fast, easy way to develop solutions for high-volume commercial, packaging and industrial printing markets. Memjet will showcase both of its inkjet technologies at the upcoming PRINT 17 trade show on Sept. 10–14, 2017, in Chicago, Illinois.

Eric Owen, general manager of commercial printing at Memjet, says, “Memjet set out to develop an additional inkjet technology that would bring quality, speed and affordability to high-volume markets. To be successful, this technology also needed to keep pace with the rapid rate of change happening in the industry. The result of this effort is DuraLink. By bringing together a long-life printhead, durable pigment ink, 100 inches (2.5 meter) maximum print width and a range of versatile modules, DuraLink enables the rapid, cost-effective development of next-generation solutions for commercial, packaging and industrial printing markets.”

Redundancy at the Nozzle Level

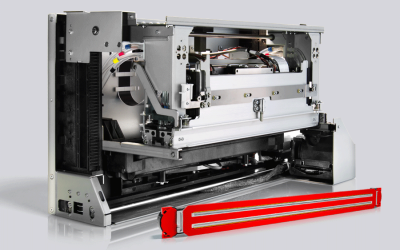

At the heart of DuraLink is a new long-life printhead. Unlike most printheads on the market today, DuraLink integrates redundancy at the nozzle level. DuraLink has 5x nozzle redundancy across 70,400 nozzles. With five nozzles printing each pixel column, if one jet goes out, it will go virtually unnoticed in the printed image.

This level of redundancy and longer printhead life result in high reliability.

The long-life DuraLink printheads require less maintenance and enable longer print runs. Moreover, printing companies no longer need to take on the cost and complexity of adding additional print bars to achieve nozzle redundancy or implementing costly image-quality monitoring systems.

“Businesses report that a key benefit of inkjet has been the way it greatly simplifies the print production process while still achieving the level of quality their customers demand,” explains Owen. “DuraLink now brings those benefits to markets that require longer print runs, making the production of these jobs faster, less expensive and easier than had been previously possible.”

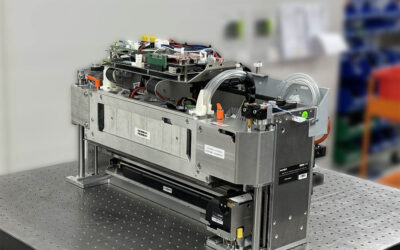

Print Modules for Stability and Flexibility

DuraLink modules provide OEMs with the building blocks to design and create a custom printing solution specific to their applications. These standardized module designs provide the system capabilities of fluidics, maintenance, and data channel management for Memjet printheads and inks, resulting in architectural system stability and design flexibility that enable the fast and cost-efficient development of solutions that meet the demands of specific markets.

OEM partners can use these modules to build customized presses that offer print widths from 8.5 inches (220 mm) to 100 inches (2,500 mm), speeds up to 668 feet per minute (203 meters per minute), one to eight colors simplex or duplex, and offset-like print quality up to 1600 x 1585 dpi.

In addition to flexibility, DuraLink has a lower cost than other printhead technologies. This, along with the available modules, allows OEM partners to affordably build powerful inkjet solutions designed to meet the needs of their specific markets.

Industry-Leading Speed and Quality

Together, the features of DuraLink provide industry-leading quality and speed to a range of commercial, packaging and industrial printing markets.